|

Improved

Alignment

Research has

verified that increasing the available power during reflow has two

significant effects:

- Increased

Power availability reduces the necessary air temperature needed

to Reflow.

- A reduction

in Reflow Temperature results in higher solder viscosity, producing

improved alignment characteristics for BGA and SMT components.

These two

important effects produce the following important advantages:

- Reduced component

and board stress

- Prevent the

possibility of scorching

- Assist in

the prevention of bridging between contacts

- Help align

BGA components more comfortably

Linear Air

Delivery

The Heat Acceleration

Chamber and delivery Nozzle Block are designed to provide maximum

air spin of the air flow to the nozzle, ensuring minimal temperature

differences across wide area packages, important for linear reflow

of CCBGA and larger devices.

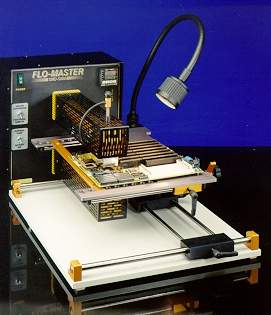

Flo-Master-Z Order Information:

- 5000-2000-Z Flo-Master 110v Z-Axis

Unit Includes: Power Supply 110v, Reflow Head with 2.500" of Z-Axis travel

(1200watts), Integrated Localized Pre-Heat System (600watts), Digital

Controller with all 4 modes of operation, 8" x 12" Frame Holder on linear

rails, Self-Contained Vacuum IC removal device, SMD Tool Kit, Halogen Light

w/ mounting bracket, Chipmaster T and Sniper Demonstration video, Foot

Pedal, Power Cord, three user-selected Reflow nozzles, and two user selected

pre-heat nozzles.

- 5000-2002-Z Flo-Master 220v Z-Axis

Unit Includes: Power Supply 220v, Reflow Head with 2.500" of Z-Axis travel

(1200watts), Integrated Localized Pre-Heat System (1200watts), Digital

Controller with all 4 modes of operation, 8" x 12" Frame Holder on linear

rails, Self-Contained Vacuum IC removal device, SMD Tool Kit, Halogen Light

w/ mounting bracket, Chipmaster T and Sniper Demonstration video, Foot

Pedal, Power Cord, three user-selected Reflow nozzles, and two user selected

pre-heat nozzles.

|

Benefits:

- Enables true

reverse manufacture rework

- Low Temperature

removal of components

- Maintains

integrity of existing solder

- Automatic

removal of components at eutectic stage

- All types

of PCB products accommodated

- Total area,

simultaneous reflow of component

- Run continuous

or pulsed

- Rework soft

plastics and sensitive components requiring short heat cycles.

Specifications:

- Power: 110V-1800

Watts, 220VŠ2400 Watts

- Current:

16.36 Amps @ 110V, 10.91 Amps @ 220V

- Dimension:

26" x 12.75" x 16" (660 x 324 x 406 mm)

- Board Holder:

Standard 8"x12" (203 x 304 mm)

- 3 Reflow Nozzles

included: (User may select alternatives)

- 2 Preheat Nozzles:

- Air Velocity:

(Both Heaters) <12.7 CFM

- Vacuum: Internal

(Optional factory Air)

- Air Source:

Internal

- Controller

(Both Heaters): Fuzzy logic PID Profile Storage

- 4-Axis X-Y

Table Built In: 19.0" x 15.50" (482.6 x 393.7 mm)

- Operation:

Pulsed or Continuous

- Maximum Board

Size: 32" x 24"

Preheat

A bottom preheat

and in-process heat source, ensures stability of board temperature,

reducing the necessary top reflow temperature, thereby following

a more precise profile structure for the component undergoing rework.

Temperature

Profiles

A range of temperature

profiles are installed for bottom and top controllers and each thermal

profile may be custom programmed, enabling different combinations

of preheat and removal temperatures to be selected.

Mechanical

Control

The Flo-Master

has been engineered to operate on a standard workbench and includes

a built-in X-Y Table for precise alignment. Each of the axis can

be locked for optimum control.

|