Radiant Hot Plate SMD-6000

Overview

A Hot Plate system designed especially for the Electronics Industry – Soak, Preheat, Burn In, Reflow, Pull Test & other uses

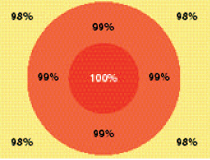

Thermal Imaging of Surface Temperature Profile Chart

|

| Radiant EnergyThe Radiant Hot Plate has been engineered to provide an efficient High Mass Digitally Controlled Direct Radiant Energy source for “in-process” or “off-line” preheat and bake requirements of components and circuit boards.

Safety First

Four (4) Heat Shield Guards are installed to protect the user. The Digital Controller is preset to a mximum of 350°F (176°C), but can be increased upon request. It is recommended that the Hot Plate be placed in a zoned area and a “Caution” notice posted that a hot surface is present.

Specifications:

- Dimensions 12″ x 6-1/8″ x 13″ (305 x 156 x 330 mm)

- Weight 17.5 lb (7.9 kg)

- Power 110V-1500 Watts, 220V-1600 Watts, 50/60 hz

- Maximum Temperature

- Standard Factory Regulated 350°F (177°C) ±2°F

- Special Factory Regulated 700°F (371°C) ±2°F

- Maximum Permitted Weight on top of Hot Plate 40 lb. (17.1 kg)

- Cord Three Wire

- Heating Element Ceramic

- Controller PID Fuzzy Logic Digital

- Radiant Plate Cast Aluminum 12″ x 12″ (305 x 305 mm)

- Stabilizing Period 45 Minutes

- Timer Push to start, push to stop

- ESD Rating <0.004V

- Safety Shielding Four (4) Side Guards

- Fuse 15 Amps

- Switching Solid-State 430 m/s

|

Large Area Stability

The Radiant Hot Plate is a non-static generating and includes 144 sq. inches of cast aluminum, selected to ensure stability of performance and close tolerance over the surface of the Hot Plate.

Digital Control

A PID Digital Closed-Loop Programmable Controller measures the temperature feedback via a “K” type thermocouple. A temperature setting may be calibrated and stored within the Controller and once set will be maintained to ±2°F.

Order Information

Part # Description

High Temperature Reflow Hot Plate

Part # Description

Radiant Hot Plate Accessories

Part# Description

- 8100-2424 Board Holder for Hot Plate

- 8100-1102 Chipmaster Riser Platform

- 8100-1103 Board Holder Riser Platform

|

Shop Online

Shop Online