Overview:

A proven bonding repair and production system for Liquid Crystal Display, which are bonded by Heat Seal Connector contacts (HSC) or Reflow Solder contacts, as used in Pagers, Portable Radios, PCMCIA and PCS devices.

|

Automatic Control

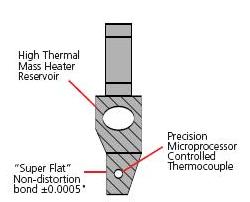

A closed-loop system continually compensates for “Set Point” of temperature drop and overshoot, which is accomplished by a centrally located, low mass (fast response) thermocouple sensor, located directly within the Hot Bar.

The close tolerance temperature control eliminates thermal stress, delamination and heat degradation, providing a major advantage in the reliability of the bonded components.

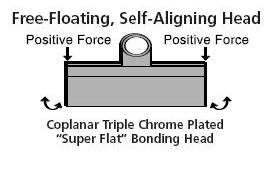

Bonding Head

The BondMaster uses a self-aligning, free-floating Bond Head (Hot Bar Thermode), which is optomized by a Temperature Controller providing accurate and reliable temperature-time cycle control.

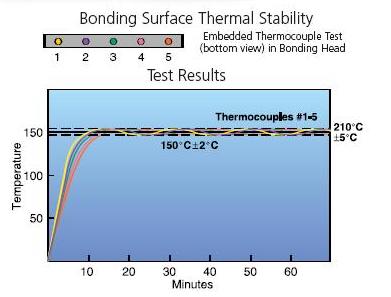

Bonding Thermal Stability

Uniform heat distribution throughout the Hot Bar is critical in ensuring a reliable bond.

Indgredients for a Successful Bond

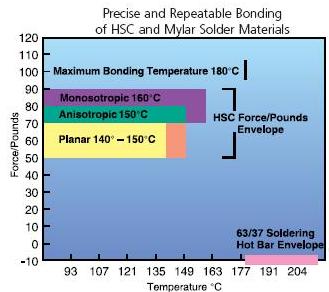

- Time

- Temperature

- Profile

- Pressure

Time, Temperature, and Profile are controlled by the PID Controller, which stores the correct program for the bond.

Pressure

Pressure is applied by a calibrated tension, maintained by a Bearing Carriage and determined by a Thumb Wheel Adjuster. A Locking Pin protects against intervention.

Bonding Lock

Once the subject is in place under the Bond Head and the pressure adjusted by the Thumb Wheel, the Bond Head is placed in position by a Locking Lever, which will remain until the bond time is completed.

Features

- HSC, Mylar, PCMCIA, Flexible Circuit connections

- Microprocessor controlled

- Self-contained, no PC or factory air required

- Linear pressure control

- Precise temperature control and profiling

- Repeatable process control

- Continuous or pulse operation

- Pre-stored profile groups

- User programmable

- Floating and self-aligning Bond Head

- Thermal bonding reservoir

- “Super Flat” bonding surface

- Thermal stability throughout bonding cycle

- No silicone barrier required

APE also offers video narrated trials to help in the evaluation process, our lab technicians will perform your job and return the completed work with the video.

|

enlarge photo (Picture 2)

enlarge photo

enlarge photo |

|

Click Here To Purchase!

Order Information

APE Part# Motorola Part# Description

9000-1000 R1346A BondMaster 60Hz 110V

9000-1002 R1347A BondMaster 50Hz 220V

9000-1010 0180304E22 Universal Bonding Fixture

8200-1370 0180304E25 HSC Bond Tape, 3 pack

8200-1360 0180304E72 HSC Bond Tape, 6 pack |

|

BondMaster Fixturing

The BondMaster has been engineered to enable rapid interchange of differing product assemblies, not only for Pager products listed but also for producttion assembly of LCD and Flexible Circuits.

Fixturing

We are pleased to offer advice in developing a Fixture. However in order to keep costs to a minimum we suggest that our customers use either in-house or local facilities to fabricate fixture requirements.

|