Cost Effective With the proliferation of new packaging technology and costly SMT PCB’S, rework challenges have developed to safely repair and rework boards with repeatable process control. In 1991 A.P.E. introduced the ultimate cost effective SMT solution….The Chipmaster!

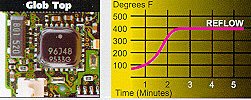

Power Reflow What makes the Chipmaster different from other Hot Air rework machines? “POWER”…Its 1200-Watt heater reworks sensitive components at original Convection Oven temperatures, typically less than 450°F (232°C), thereby reducing the temperature to the component and surrounding area.

Low Temperature Advantage

The advantages of this patented design have only recently become recognized, particularly with the research into BGA sphere behavior under differing temperatures. For example, the lower the temperature, the greater the viscosity of the sphere, therefore, it follows that the greater the viscosity, the more definite the alignment characteristics of the sphere during reflow.

Solder Integrity

The following micro sections indicate the superior quality of a solder junction when operating at a Low Temperature using the Chipmaster.

|

Chipmaster rework temperatures

At 400 to 450°F (204 to 221°C) Convection temperature integrity of solder remains intact.

|

Common low power rework temperatures

At >475°F integrity of solder begins to break down, this is a problem with other rework systems.

|

|

Wide Ranging

Work on traditional SMT components to the newest style BGA’s!

Specifications:

- Power 1200 Watts

- Current 10.90 Amp @ 110V, 5.45 Amps @ 220V

- Dimension 22.25″ x 9.25″ x 8.62″ (362 x 235 x 219 mm)

- Board Holder Standard 8″ x 8″ (203 x 203 mm)

- Nozzles included: (User may select alternatives)

- 8100-0000-44 0.80″ x 0.80″ (20.3 x 20.3 mm)

- 8100-1424 0.71″ x 0.40″ (18.0 x 10.2 mm)

- 8100-1075 1.00″ x 0.75″ (25.4 x 19.0 mm)

- Temperature Celsius or Fahrenheit

- Air Velocity <12.7 CFM

- Vacuum Internal Pump

- Air Souce Internal Blower

- Controller Fuzzy logic PID

Click Here!- To Purchase |