| Rework larger PCB’s safelyA common problem in reworking larger circuit boards, typically greater than 16″ x 14″ (406 x 356 mm) is warp during the local heating process. This problem can also be experienced on smaller boards depending upon layer structure and connection distribution. The Chipmaster Radiant solves the warpage problem!

High mass radiant energy

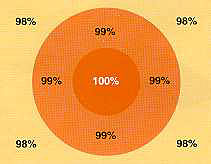

The Chipmaster Radiant delivers 144 sq. inches of digitally controlled radiant energy accurate to ±2°F, once calibrated. Its cast aluminum surface may be machined for unique profiling for one or more circuit boards.

Thermal Imaging Surface

Low Temperature Operation

When equipped with the Low Temperature, High Power technology of the Chipmaster Radiant, youÕll be able to rework soft plastic components at less than 410°F, which would otherwise distort or melt down with conventional systems.

Articulating Board Holder

The 8100-2424 articulating Board Holder is an important dual-axis mechanism, which positions the PCB over the radiant surface for rework to the circuit board and returns the PCB to its original cool start location for preparation and cleaning.

RAD-6000 System includes:

- 8100-1003 Chipmaster with Profile Storage Controller

- 8100-6000 Radiant Preheater 12″ x 12″ (305 x 305 mm)

- 8100-2424 Board Holder

- 8100-1102 Chipmaster Riser Platform

- 8100-1103 Board Holder Riser Platform

- 8100-0598 Halogen Light 110V

- 8100-1097 SMD Tool Kit

- 8100-1649 Nozzle Kit three (3) piece

|

Specifications:

- Chipmaster 8100-1003 110V, 60Hz CSA

- Chipmaster 8100-1023 220V, 50Hz CE

- Power 1200 Watts

- Current 10.90 Amp @ 110V, 5.45 Amps @ 220V

- Dimension 22.25″ x 9.25″ x 8.62″ (362 x 235 x 219 mm)

- Board Holder 8100-2424 24″ x 24″ (610 x 610 mm)

- Nozzles included: (User may select alternatives)

- 8100-0000-44 0.80″ x 0.80″ (20.3 x 20.3 mm)

- 8100-1424 0.71″ x 0.40″ (18.0 x 10.2 mm)

- 8100-1075 1.00″ x 0.75″ (25.4 x 19.0 mm)

- 8100-1414 1.40″ x 1.40″ (35.6 x 35.6 mm)

- 8100-0000-20 0.50″ x 0.50″ (12.7 x 12.7 mm)

- 8100-0000-68 1.10″ x 1.10″ (28.0 x 28.0 mm)

- Temperature Celsius or Fahrenheit

- Air Velocity <12.7 CFM

- Vacuum Internal Pump

- Air Souce Internal Blower

- Controller Fuzzy logic PID

- Hot Plate 8100-6000 110V 60Hz CSA

- Hot Plate 8100-6002 220V 50Hz CE

- Controller Fuzzy Logic PID

- Surface Area Cast Aluminium 12″ x 12″ (305 x 305 mm)

Link to Hot Plate webpage – Click here!

Purchase Radiant Package – Click here!

|

Shop Online

Shop Online